Double-Inlet Centrifugal Fan Impeller

- Products

- Double-Inlet Centrifugal Fan Impeller

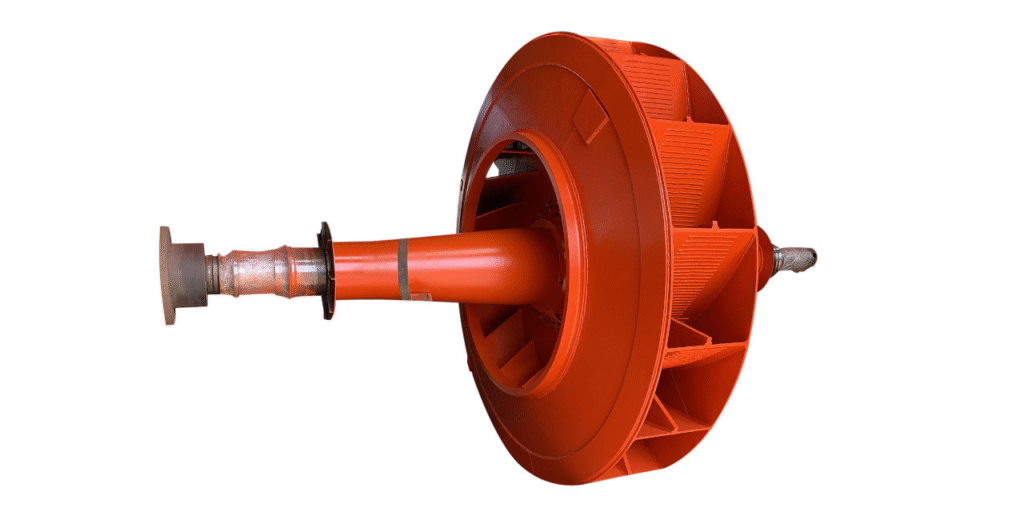

Double-Inlet Centrifugal Fan Impeller

Product Overview

The double-inlet centrifugal fan impeller is engineered for high-efficiency air movement in large-scale ventilation and air handling systems.

Featuring dual inlets, this impeller design allows air to enter from both sides, effectively doubling the airflow compared to single-inlet counterparts.

This configuration is ideal for applications requiring substantial air volume with consistent pressure, such as HVAC systems, industrial ventilation, and air purification units.

Key Features

- Dual Inlet Design: Enhances airflow capacity by allowing air entry from both sides, resulting in increased volume without compromising pressure stability.

- High-Efficiency Blades: Available in forward-curved or backward-curved blade configurations to suit specific performance requirements, ensuring optimal efficiency and reduced energy consumption.

- Robust Construction: Manufactured from high-quality materials such as galvanized steel, stainless steel, or aluminum, offering durability and resistance to corrosion in various operating environments.

- Dynamic Balancing: Each impeller undergoes precise dynamic balancing to ensure smooth operation, minimize vibration, and extend the lifespan of the fan assembly.

- Versatile Mounting Options: Designed for compatibility with both direct-drive and belt-drive systems, providing flexibility for integration into diverse mechanical setups.

Technical Specifications

- Impeller Diameter Range: 200 mm to 1,000 mm (7.9 inches to 39.4 inches)

- Airflow Capacity: 2,500 to 100,000 m³/h (1,470 to 58,860 CFM)

- Static Pressure: 200 to 1,500 Pa (0.8 to 6 inches w.g.)

- Operating Temperature: -30°C to +100°C (-22°F to +212°F)

- Blade Configurations: Forward-curved or backward-curved blades

- Material Options: Galvanized steel, stainless steel (304/316), aluminum

Applications

- Heating, Ventilation, and Air Conditioning (HVAC) systems

- Industrial ventilation and exhaust systems

- Air handling units and cleanroom environments

- Dust collection and filtration systems

- Boiler forced and induced draft applications